Here are some care tips hints and troubleshooting information divided into two sections, one that applies to all clocks and one specifically for grandfather clocks:

Setting The Time:

Using the minute hand only, advance the hand forward, pausing as necessary to allow the clock to chime or strike. On most modern clocks, the minute hand can be safely moved backwards as well. If firm resistance is felt when moving the hand in either direction – STOP. Forcing the hand can cause damage.

Synchronizing The Strike:

If the strike count at the top of the hour doesn’t match the time on the clock, simply move the hour hand to match the strike count, then set the time using the minute hand. This may seem confusing at first, but strike mismatches almost always result from someone accidentally moving the hour hand when setting the time, so the hand merely needs to be moved back where it belongs.

What To Do When Clock Stops:

First, be sure that a spring powered clock is fully wound until the key won’t turn any further. Don’t worry, you can’t “overwind” a clock. It is important to wind all arbors on the clock because a rundown chime or strike train can stop the clock. Look at the hands to be sure they are not catching on each other or touching the dial. For wall clocks, try tilting the clock slightly to one side then the other, and listening to see if the ticking sounds more even. Cuckoo clocks are especially affected by this as they are often pulled off of level when the weights are raised. If the clock runs for some time before stopping, try writing down the times that it stops. If you call with this information, we may be able to provide more help.

Lubrication:

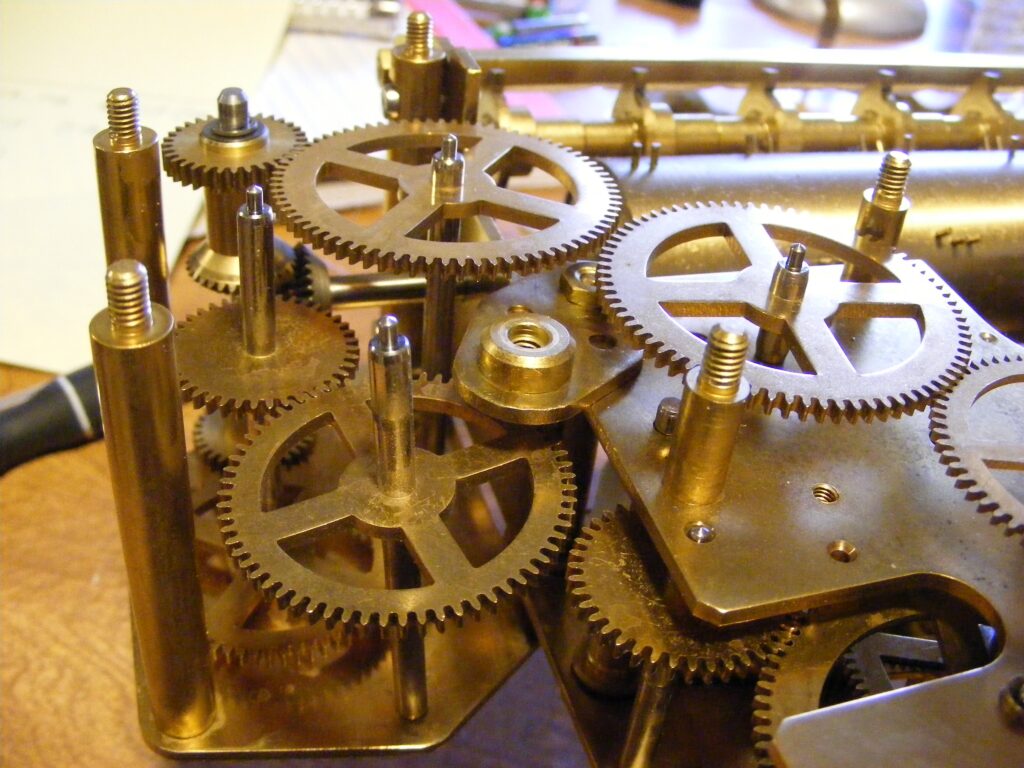

Servicing of mechanical clocks including oiling for the movement should be done at least every five years. Fresh oil at the pivots helps flush dirt away, helps to thin old sticky oil and will act to stop the oxidation that causes rapid wear. Because of the precise placement of the small amounts of oil necessary, it is also easy to over oil a movement. It is never a good idea to spray any type of lubricant into the clock as this will gum up the movement, attract dust and may even dissolve the protective coating applied to most modern clock movements. Unless you are already familiar with what is needed to lubricate your clock it is better to leave this job for us. The buildup attracted dirt resulting in the green and black deposits shown and led to the need to overhaul the movement.

GRANDFATHER CLOCK REPAIR & SERVICE

Handling and Cleaning:

When handling the weights or pendulum, ALWAYS protect them by wearing cotton gloves or using a clean cloth. The acids on hands will eat through the protective coating on these parts and cause permanent stains. Never apply cleaning products to these parts, remove dust with a clean dry cloth only (no paper towels!). If the inside of the door glass needs cleaning always, apply the cleaner to a cloth and then wipe the glass rather than spraying it. The case may be cleaned and polished the same as any other fine furniture.

Winding:

When winding the weights in a clock with chains, it is OK to keep the weights from swinging with your free hand (remember to wear gloves!). Pushing up on the weights from underneath is a bad idea as it is very easy to derail the chain this way, It is good practice to take note of what point the weights will hit the top and stop a couple of inches short of this point. If the clock is key wound, it most likely has a device called a stop works built in to stop the weights from hitting, so it should be safe to wind them fully.

Uneven Ticking:

If the ticking sounds uneven (out of beat), give the pendulum a much wider swing than normal by bringing it close to the side of the case and letting go. This sets the beat and should solve the problem. Some smaller “Grandmother” and all antique clocks use other methods of beat setting that are best done by a clock maker.

Timekeeping:

If your clock is not keeping proper time it can be adjusted by turning the nut at the bottom of the pendulum. Raise this nut to speed up, lower it to slow down. A good way to start is to move this nut one full turn when winding the clock. Then start the pendulum and set the time. At the end of the week, compare the gain or loss to the previous week.

Example – previous week had a loss of 10 minutes and after raising the nut 1 turn it lost 7 minutes. So, 1 turn of the nut changed the timekeeping by 3 minutes per week. Another 2 1/2 turns of the nut should be about right.

CONTACT US TODAY

If you are still having issues with your antique clock, we welcome you to contact us today! The team at WNY Clock Repair would be happy to provide the right clock repair services you and your clock need. We even offer in-home grandfather clock repair across the Buffalo, NY area.